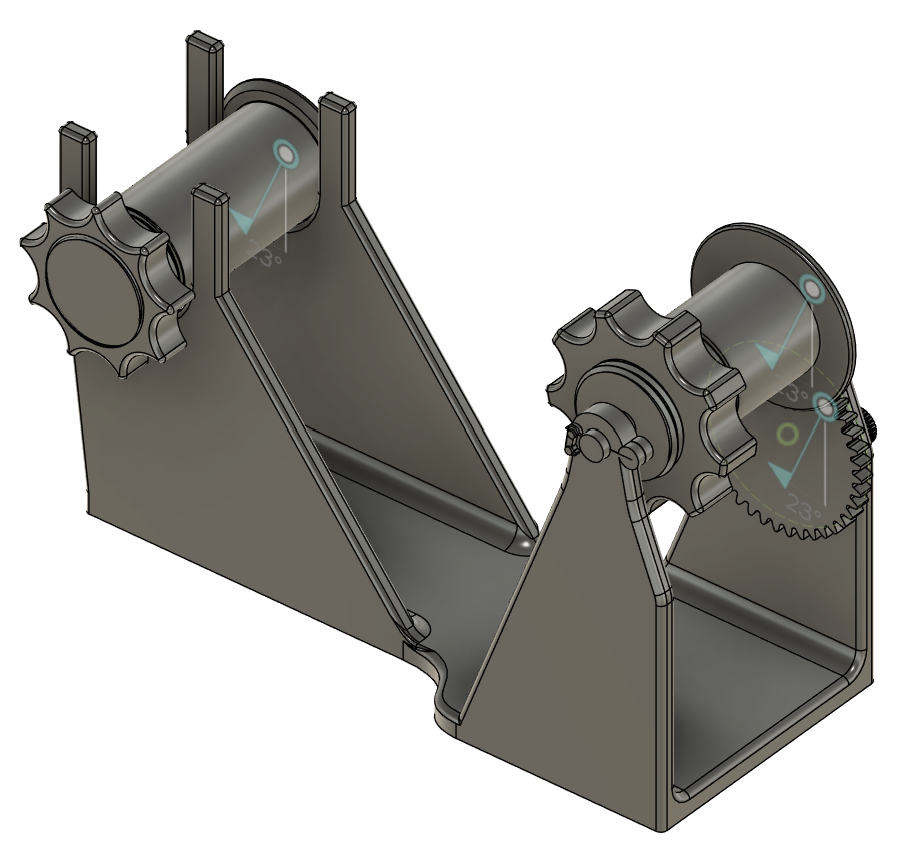

Manual filament spool winder

Manual filament spool winder

Print Profile(3)

Description

This is a manual filament spool winder inspired by the bmsluite model, originally made for splicing and winding multiple spools of leftover filament onto a single roll.

From there it has been modified to achieve a simple and effective fully manual filament spool winder, which does not need any metal parts or other parts and which will help you rewind your filaments easily.

Its main use is to change the filament from one spool to another, for example to recharge filament in Bambu Lab spools for greater and better use of the AMS.

It has also been redesigned and separated into the necessary parts with connectors so you can print it on your Bambu A, X or P series

I have done test with three complete ones, all made with Bambu Pla Basic, 25% filling should be enough, If you have issues you can increase the filling of the parts that are subjet to greater stress like hand crank (recomended 65% filling) or use PETG/ABS/ASA. In addition you can also vary the printing position to give greater strength.

A drop of lubricant on the gears and hand crank will help ensure smoother, longer-lasting operation without issues

Enjoy it!!

Comment & Rating (167)