Vacuum former laser/print

Vacuum former laser/print

Print Profile(0)

Description

Summary

Thanks for the idea Gilles Pinault (https://www.thingiverse.com/gillespinault/designs).

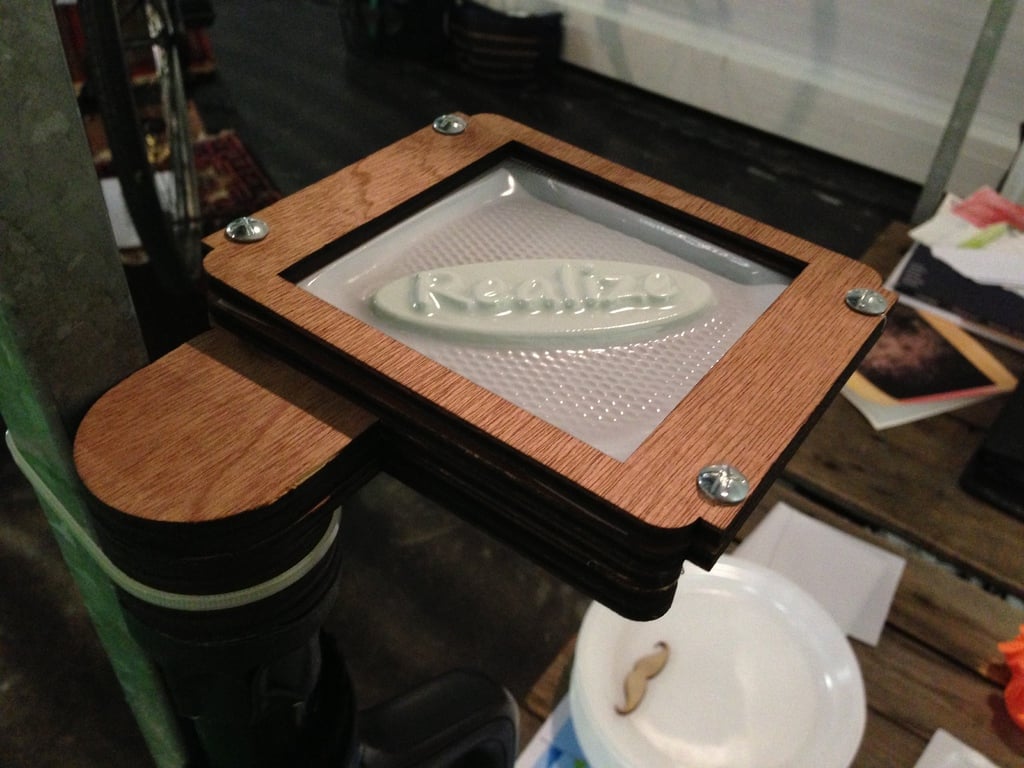

This is my laser cut and 3d printed (not recommend) vacuum forming design. The laser-cut files were designed to be cut on a 15/23 Laser cutter. I would not try to 3d print these because it is a lot of flat parts.

Use anything that is easy to trap air and use glue or something to keep the air in the will work. Use a hose on a shop vac to suck down the heated plastic on the object. Make sure the objects are easy to suck air through like this bar (https://www.thingiverse.com/thing:3182100) or like this random bracket (https://www.thingiverse.com/thing:1478563/files).

Instructions

Materials

⚈ Laser Cutter or 3D Printer (LOTS OF PLASTIC)

⚈ Acrylic or Wood for base material

⚈ shop Vacuum

⚈ Oven or heat gun

⚈ hot glue

⚈ hot glue gun

⚈ some sort of plastic to form with

Optional

◼️ aerosol can

◼️ cooling fan

steps

⚠️WARNING- Hot plastics used

➡️➡️➡️First, check over the files and make sure you can fit them on your machine. Then you can start your files by laser cutting or even CNC them. But try to steer away from 3d printing it since it is flat and uses a lot of material.

➡️➡️➡️Second, check out the parts and see if there are any cracks or miss-cuts. Then prepare the glue gun and clean the parts for gluing. start gluing the parts that have a loop glue together. after gluing you should have two extra parts which is the frame. also, sand down the 3D printing model so your mold comes out smooth.

➡️➡️➡️Third, hook up the vacuum to the parts. They use the vacuum on the former and to test put a piece of paper on the top and see if it sucks. If It doesn't try gluing them together again and check if the material blocks air from passing through.

➡️➡️➡️Fourth, try to find a thin plastic sheet to form with and heat it with the oven or heat gun. You will know when the plastic is at the right temperature when it droops down. Then place your object on the platform and turn on the vacuum. Once you are ready push the plastic sheet onto the object and watch your model poke through.

➡️➡️➡️Fifth, hold the frame over until it cools when it is no more floppy. Get out the model with your hand or you can use an aerosol can to shoot air to get out the mold. then you can either use chocolate in the mold or any material you want.