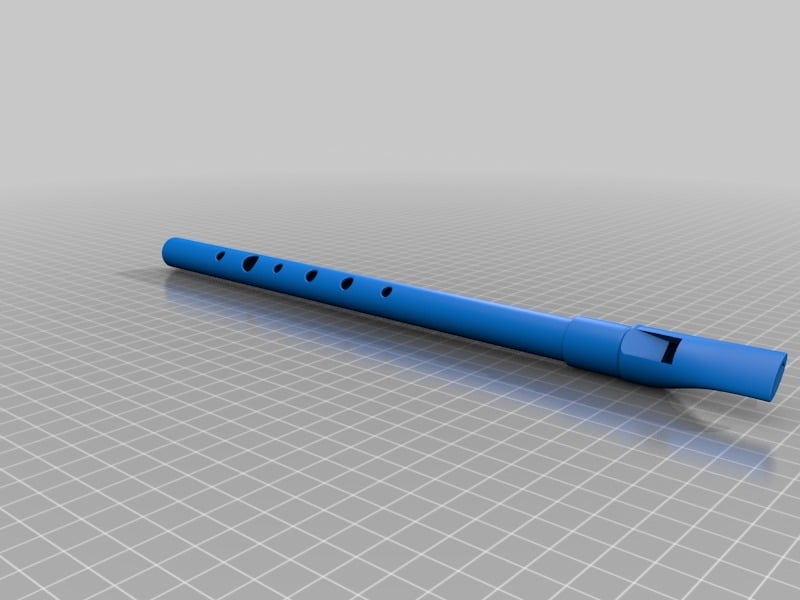

Tin Whistle (Penny Whistle) In The Key Of D

Tin Whistle (Penny Whistle) In The Key Of D

Print Profile(3)

Description

UPDATE 5/28/2024: Updated the supported print profile to achieve better tuning and fit of the main body piece.

A nice little tin whistle (aka penny whistle) in the key of D, generously created by iceman1979 on Thingiverse. Great for playing around with, taking on the go, or practicing technique. Uses very little filament (19.56g without supports)!

The model has been scaled from the original to help with tuning and fit during assembly. The fipple requires glue to secure, but the body is press fit to allow minor adjustments for tuning (you may have to file the seam a little or try your luck with scarfs). If sanding is required, fit it before gluing to ensure you're tuned right. You can make adjustments and make this flutes root note sharp, for example!

The files will print alright without supports as oriented, but I have also provided a version with some supports and brims that should remain easy to remove without needing internal cleanup, while also helping ensure the larger hole and air channel stay nicely shaped, and thus preserve tone. I found 0.16 layer height to feel nicer in the hand, but is my preference, do what you wish!

Included in the raw files are an optional assembled version that prints as a single part (Tin_Whistle_Assembled.stl), as well as a combined A and B section (Tin_Whistle_Body_Full.stl, remixed by aparitxi on Thingiverse) so you need only print and join the fipple (mouthpiece). NOTE: These files are not scaled for tuning like the others, so I would recommend scaling to 95% to then test and adjust to your liking.

Here is a sample of what the flute sounds like. Please forgive my poor technique, it's my first try, geez. Hopefully you get a sense of the sound, as well as how fun and easy this thing is; I learned Country Roads (kinda) in about 10 minutes. Be sure to completely cover the holes with your fingers and breathe gently and steadily, unlike me.

This is a remix of a model created by iceman1979 and is licensed under CC BY-SA.

Comment & Rating (23)