Tunable torque wrench

Copyright Claim

Tunable torque wrench

Boost

1

2

0

Print Profile(1)

All parts, details printing profile with necessary supports

4.5 h

1 plate

Boost

1

2

0

0

7

2

Released

Description

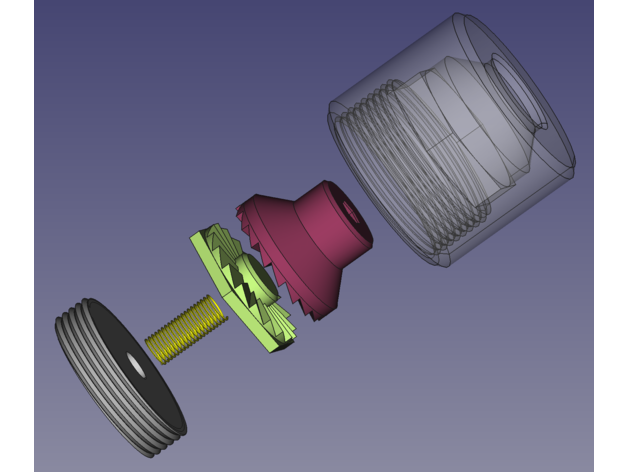

Tunable torque wrench

There are many good printable fixed torque wrench design for nozzle changing but most of them depend on the characteristics of the filament used to print the parts. This version is my attempt to solve that problem.

Features

- Adjustable torque

- Come with calibration tool

- Less depend on filament characteristics

Require parts

- 20mm d8mm spring.(I use the yellow spring that often use for printer bed)

- OD4mm ID2mm PTFE tube

- 1/4" Hex Socket Adapter (something like this https://www.amazon.com/DEWALT-DW2541-4-Inch-Socket-Adapter/dp/B0000225P4)

Hex socket matched your nozzle size

Print setting

Material : PETG. PLA is too brite as my testing and they are tent to deform under pressure.

Print setting : 5 walls, 5 top/bottom layers, 30% infill

Assembly guide

- Cut the PTFE tube into 6 segments with length of 5mm, this will be use as bearing for the top gear.

- Make sure the gears smooth. Sand the gear lightly if needed. Put some grease between the gears.

The spacer only needed if your spring is too weak.

Calibration guide

- Tighten the back tension cap

- Attach the calibration arm and hold it horizontally

- Hook a weight to other end of the calibration arm.(each 1Kg hooked to the arm equal 0.5 N∙m torque)

- Slowly loosen the tension cap until it skip

- Slightly re-tighten the tension to the point just before it skip

- The hvdt version of the calibration arm is optional. This version have slot to set a 30mm m3 bolt in to keep it from breaking

Comment & Rating (0)

All

No more

The user shared this model, but is not the original creator of it.

License

This work is licensed under a

Creative Commons Attribution-Noncommercial